SALT

TRANSPORT IN PLASTER/SUBSTRATE LAYERS

We have investigated how transport and accumulation of salt in a

plaster

depends on the underlying masonry material. Therefor the same

plaster

is

applied on two substrates of which the pores are either an order

of

magnitude

larger or smaller than those of the plaster, i.e., a plaster layer

(lime

: cement : sand = 4 : 1 : 10) on a Bentheimer sandstone or on

calcium

silicate

brick. The poresizes as measured for the various layers using

mercury

porosimetry

is given in table 1.

| Material |

nano-pores

|

micro-pores

|

volume ratio

|

| Bentheimer

sandstone |

¾

|

(40 ± 20) m

m

|

¾

|

| Calcium-silicate

brick |

(20 ± 10) nm

|

(20 ± 10) m

m

|

1:1

|

| Plaster |

¾

|

(0.7 ± 0.4) m

m

|

¾

|

Table 1. Pore sizes measured by mercury-intrusion

porosimetry.

Initially the samples were saturated with a salt-solution of

different

concentrations. Due to the differences in pore structure between

the

sandstone

and the calcium silicate brick totally different drying and

crystallization

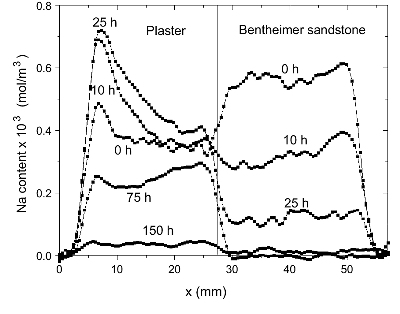

behavior is observed. In figure 1 the measured moisture

distribution

for plaster/Bentheimer sandstone as a function of time is given.

Figure 1: Moisture content in the plaster/Bentheimer

sandstone

system

during drying. The

sample was initially saturated with a NaCl solution (c = 4

mol/l

). Dry air is blown

over the top of the sample (x = 4 mm) with a flow of 0.7 l/

min

.

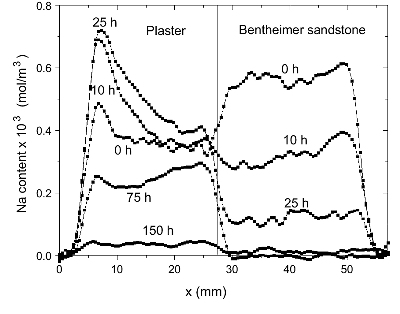

In a Bentheimer sandstone the pores are much smaller than the

substrate

and hence it is drying first. In figure 2 the the Na content as a

function

of time is given.

Figure 2. The Na content a function of time for

plaster/Bentheimer

sandstone system during drying.

As can be seen in this case almost all salt is transported from

the

sandstone into the plaster, i.e, all salt is removed from the

sandstone.

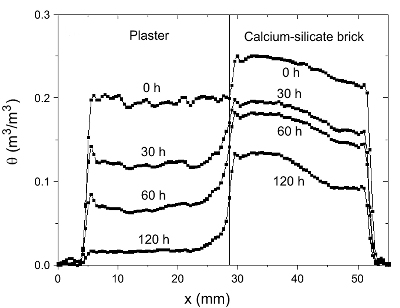

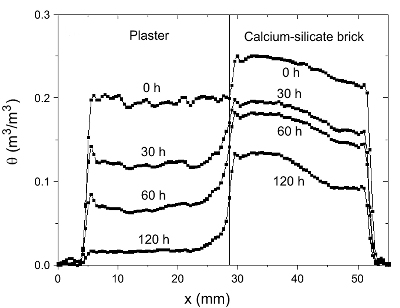

In figure 3 the measured moisture distribution for plaster/calcium

silicate brick as a function of time is given. Due to the fact

that in

this case the brick contains a large number of pores smaller

than

the plaster, first the plaster layer dries out.

Figure 3: Moisture content in the plaster/calcium-silicate

brick

system during drying. The

sample was initially saturated with a NaCl solution (c = 4

mol/l

). Dry air is blown

over the top of the sample (x = 4 mm) with a flow of 0.7 l/

min

.

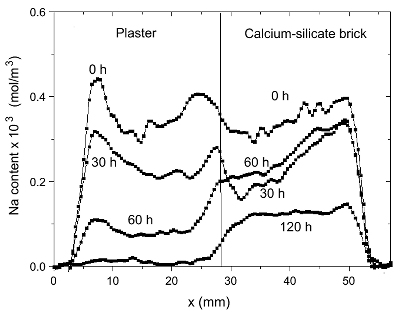

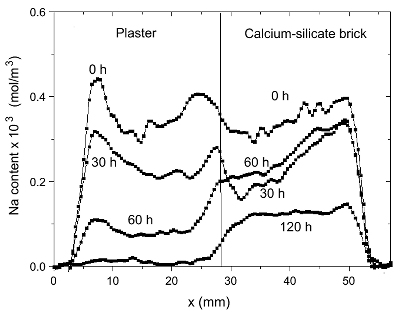

In this case a significant amount of salt will stay in the brick

and

crystallize there. Hence the efficiency for salt removal is very

low

Figure 4. The Na content a function of time for

plaster/calcium-silicate

brick

system during drying.

From these we can conclude that the performance of the plaster is

not

solely determined by the properties of the plaster itself. A

proper

matching

of the pore-size distribution of the plaster with that of the

substrate

is needed. Applying a plaster without knowledge of the substrate

might

even lead to more damage instead of less.

- An extensive description can be found in:

J. Petkovic, L. Pel, H.P. Huinink, K.Kopinga, and R.P.J.

van

Hees,

Salt transport and crystallization in plaster layers: a nuclear

magnetic

resonance study, 6th International Symposium on the Conservation

of

Monuments

in the Mediterranean Basin, 318-322, April 7-10, Lisbon,

Portugal

(2004).

J. Petkovic, L.Pel, H.P. Huinink, K.Kopinga, and R.P.J. van

Hees,

Salt

transport in plasters/substrate layers: a nuclear megnetic

resonance

study,

13th. Int. Brick and Block Masonry Conference, Amsterdam, July

4-7

(2004).

J. Petkovic, Moisture and ion transport in layerd porous

building

materials:

a Nuclear Magnetic Resonance study, Ph.D. thesis,

Eindhoven University of Technology, the Netherlands (2005).

J. Petkovic, H.P. Huinink, L. Pel, K. Kopinga and R.P.J. van

Hees,

Salt transport in plaster/substrate layers, Materials and Structures 40, 475-490 (2007)

Back

to main page

Back

to main page