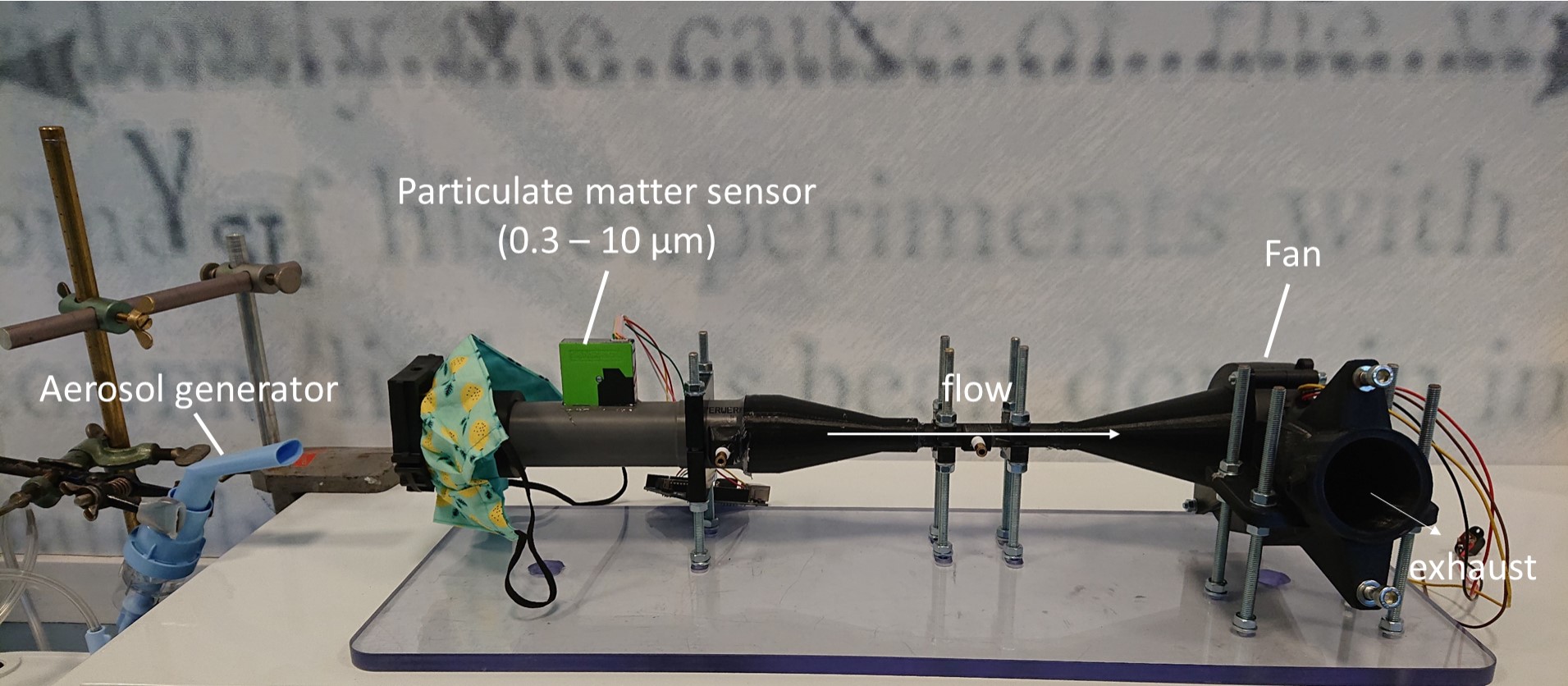

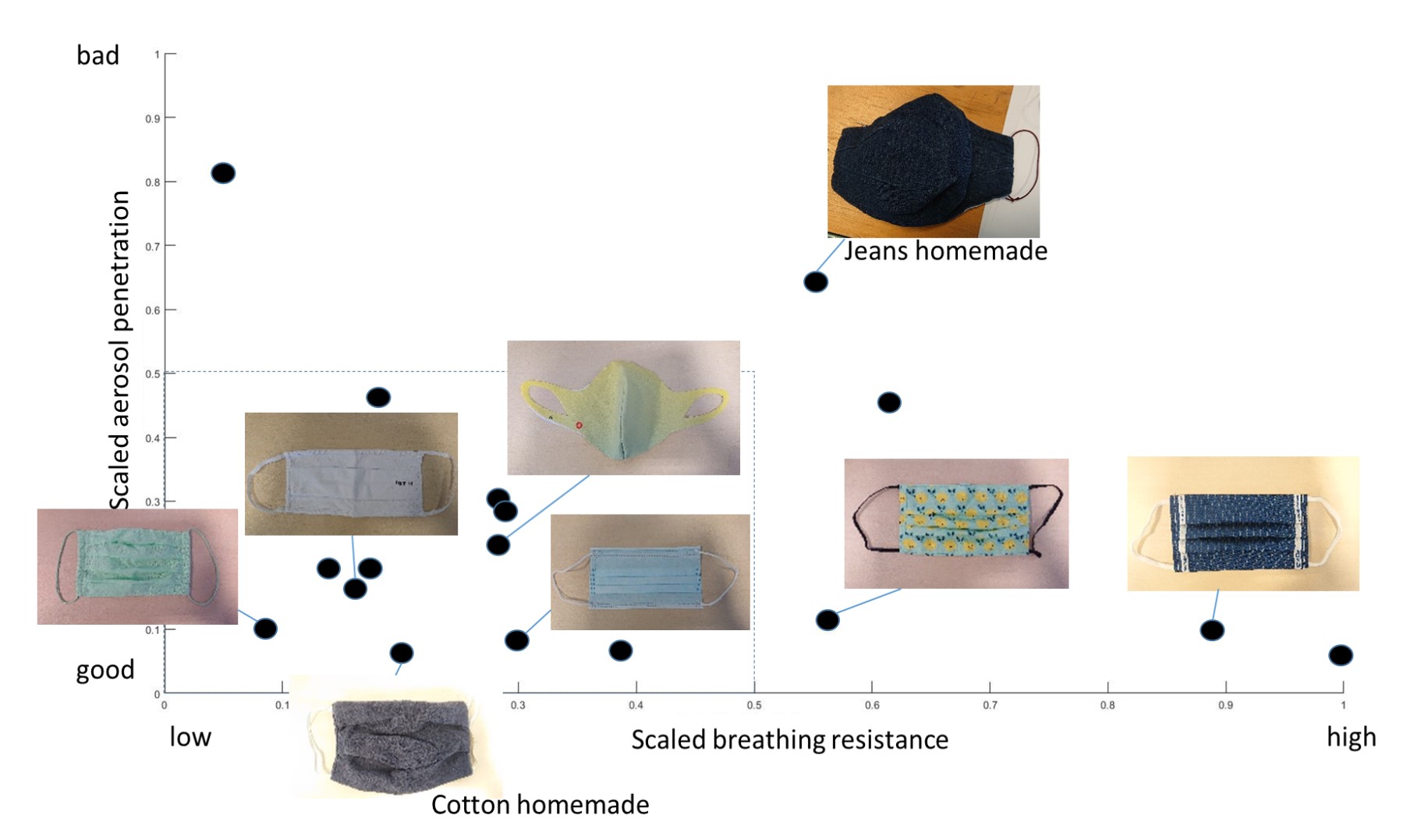

Face mask testing TU/e

Towards an open source face mask test

Department of Mechanical Engineering - Department of Industrial Design - Department of Applied Physics - Fashion Tech Farm - Darcy lab

Leo Pel, Kevin Vos, David Smeulders, Marina Toeters, Anne Lamers, Henri Vliegen, Gerard van Hout

For specific questions contact Kevin Vos: k.g.m.vos@student.tue.nl

____________________________________________